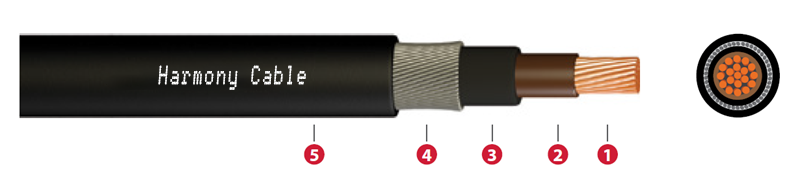

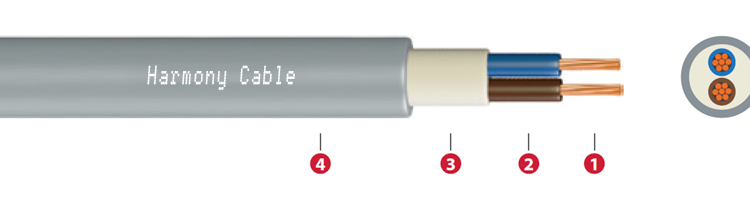

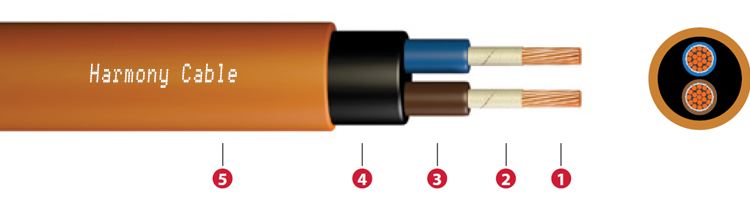

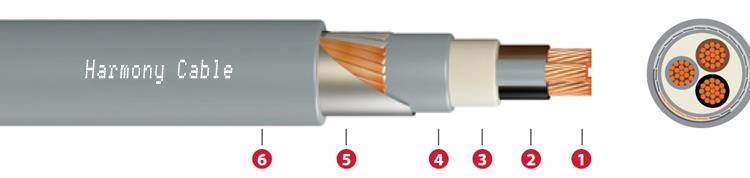

Constructions

| 1-Conductor | Solid or stranded copper (Class 1 or Class 2) |

| 2-Insulation | Cross linkable polyethylene (XLPE) |

| 3-Filler | Halogen free flame retardant (HFFR) |

| 4-Armour | Galvanized round steel wire (GSWA) |

| 5-Outer sheath | Halogen free flame retardant (HFFR) |