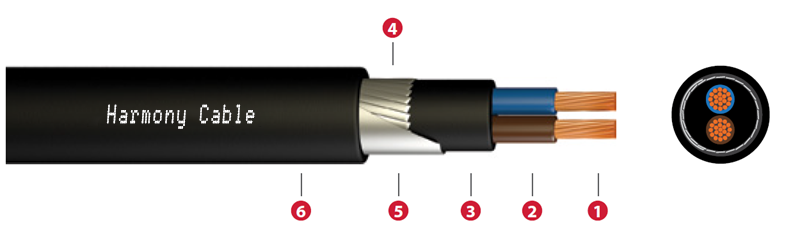

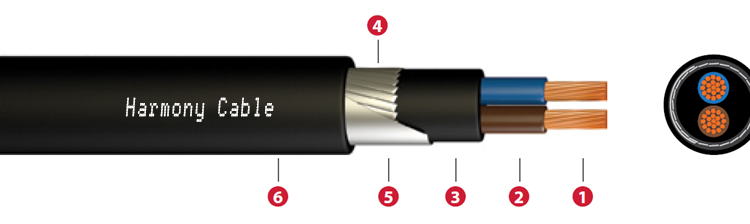

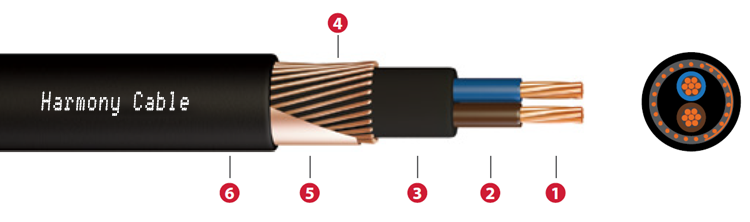

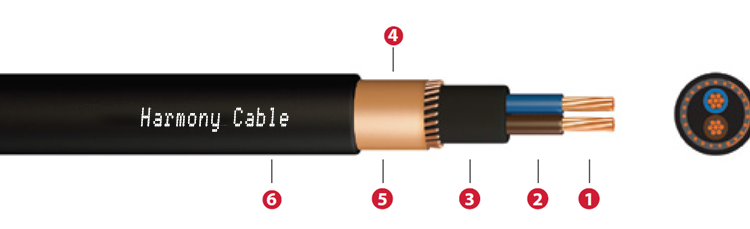

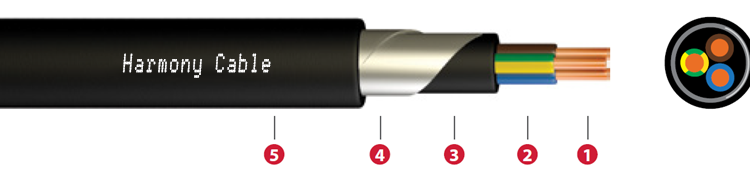

Constructions

| 1-Conductor | Solid or stranded copper (Class 1 or Class 2) |

| 2-Insulation | Cross linkable polyethylene (XLPE) |

| 3-Filler | Polyvinyl chloride (PVC) |

| 4-Armour | Galvanized flat steel wire (GSWA) |

| 5-Tape | Galvanized steel tape (GSTA) |

| 6-Outer sheath | Polyvinyl chloride (PVC) |